Hunter Custom Molding™ Solutions

- Plastic Injection Molding

- Mold Design

- New Mold Development & Sourcing Management

- Insert Molding

- Over Molding

- Prototyping

- 3D Printing

Hunter Custom Manufacturing™ Solutions

- Pad Printing

- Hot Stamping

- Ultrasonic Welding

- CNC Mill & Lathe

- Full Assemble (Manual and Automated)

- Kanban/VMI

- Full Supply Chain Management

- Retail Packaging

- Prototyping

Industry Experience

We develop comprehensive manufacturing solutions for a diverse array of industries. Hunter Custom Manufacturing is proud to serve the following industries:

- Aerospace

- Medical Device

- Laboratory Consumables

- Specialty Industrial

- Batteries

- Automotive

- Consumer Product

- Water Management

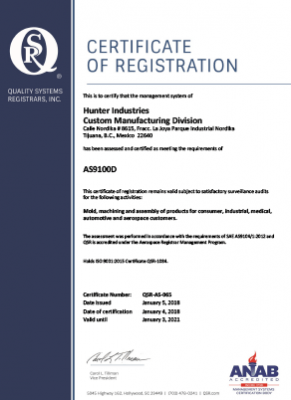

In Mexico, we are one of a few Plastic Injection Molders who are AS9100 certified.

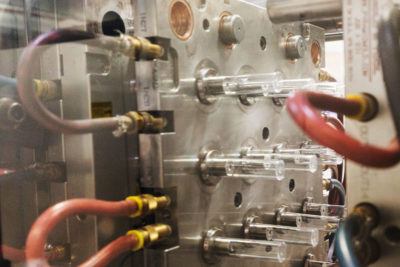

Plastics Manufacturing

Injection Molding (30 – 700 Ton)

Pad Printing and Stamping

Ultrasonic Welding

Global Logistics

International Logistics

Resin Storage in Silos

Distribution Services

Value Added

Full Assembly (Manual & Automated)

Kanban/VMI

Fully Equipped Tool Room

We Are Global

Our state-of-the-art tool room is equipped with the latest technology, and our expertly trained toolmakers are ready to support your tooling needs.

Injection Molding Machines & 3D Printing

We have 118 additional injection molding machines in our manufacturing plant in Tijuana, Mexico, including:

- 30 – 618 Ton Nissei

- 30 – 300 Ton Haitian

- 55 Ton JSW

- 55 – 110 Ton Arburg

- Stratasys Fortus 250

- Stratasys Dimension Elite

TOOL ROOM – Tijuana, Mexico

Our tool room in Tijuana operates 20/6 and is supported by Design and Tool Fabrication Managers, as well as a General Manager for Tooling who oversees operations.

| Machine Equipment | Computers and Software | Hardware | |

|---|---|---|---|

| Haas CNC VM-3 & VF-2 | Ultrasonic Cleaner Machine | Solid Works | 4″ x 8″ Steel Work Benches |

| Mill Lagun FTV-2S | Okamoto Surface Grinder | Master Cam License | Standard Work Benches, and Computer Work Benches |

| Prototrak System for Lagun Mill | Furnace Dual Chamber | Torit Extraction System | Steel Storage Rack |

| Grinder-Mitsui 6″ x 18″ MSG-205MH | Grinder-Mitsui 6″ x 12″ | Fake Wall, Power Drops, Transformers, Supervisor’s Office | Kennedy Rolling Tool Boxes |

| EDM-Mitsubishi Sinker EX8 with Tooling | EDM-Mitsubishi Wire | Measuring Equipment | Strong Hold Storage Cabinets |

| Dake VH-24 Vertical Band Saw | Haas – Lathe CNC | Brown and Sharpe Optical Comparators | Jib Crane |

| Sunnen Honing MBB-1680-MS with Tooling | Conventional Lathe | Cress Heat Treat Oven C2121/942 | Vehicle to Transport Molds |

| Saw DoALL Horizontal C-916A (small model) | Welding Machine | Small Measuring Instruments | In / Out Mold Area |

| Dake Corp. Hydraulic Press, 25 ton | Mold Die Tipper | Microscope | Granite Table |

| Die Sep Mold Trimmer | Creo SW |

TOOL ROOM – San Marcos, California

Our tool room in San Marcos designs and fabricates molds for our Irrigation business. A General Manager for Tooling oversees the operations.

| Machine Equipment | |||

|---|---|---|---|

| Mill Roders RP600 | Ultrasonic Cleaner Machine | Grinder Deckel Cutter | Saw DoALL Horizontal C-916A |

| Mill Mazak V-515/40N | Grinder Baldor | Lathe Victor | Saw Dake Coldsaw MOU989030 |

| Mill Mazak V-550 | Grinder Mitsui 6X12 MSG-200MH | Lathe Cadillac Longbed | Saw DoALL Vertical 2013-10 |

| Lathe Mazak QT250 | Sunnen Hone | Mill Lagun Protatrac FTV-2S | EDM Mitsubishi Sinker EA12V |

| Haas Lathe CNC | Shigia OD ID Grinder | Mill Bridgeport Ezpath | EDM Mitsubishi Sinker EX8 |

| Bridgeport EZ Path Lathe | Grinder Okamoto 1624DX | Mill Lagun Protatrac DPMV3 | Mill Haas VM1 |

| EDM Mitsubishi Wire CX20 | Grinder 10×48 Belt | Mill Bridgeport Protatrac |

Global Logistics & Operations

Our Global Logistics Team enables us to procure raw materials and deliver finished goods to 125 countries.

The team also supports domestic and offshore tool procurement for our business partners.

Quality Control

We have equipment and measuring instruments to monitor your dimensional, cosmetic, and functional specifications. Our inspection and process control equipment support a reliable injection molding operation to ensure the highest quality.

SMARTSCOPE QVI

Flash Measurement System

VISION SX45

Stereo Microscope Boom Stand

ZEISS CMM

Coordinate Measuring Machine

INSTRON MF20

Melt Flow Index

MICRO VU SD 312

High Precision 2D and 3D Measurement System

Quality Is Our Highest Priority

Our inspection and process control equipment support a reliable injection molding operation. We have equipment and measuring instruments to monitor customer’s dimensional, cosmetic and functional specifications.

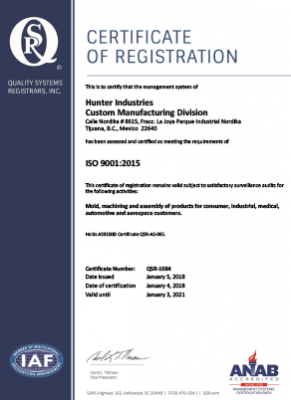

We are ISO 9001:2015, AS9100 Rev. D, ISO 13485:2016 (Medical Device), and CTPAT certified.